Increased Ventilation Rates

National Benefits of Increased Ventilation Rates

The primary standard for minimum ventilation rates in commercial buildings [1] specifies a minimum ventilation rate of 17 cfm per person for offices, using the standard’s default value for occupant density. A recent analysis [2] estimated the benefits and energy costs of various increases in ventilation rates in U.S. offices. Existing ventilation rates were estimated using data from a survey of 100 U.S. office buildings [3]. In one scenario, ventilation rates were increased to 32 cubic feet per minute (cfm) per person in the fraction of the office building population that was estimated to have lower ventilation rates. Approximately 30% to 40% of the measured existing ventilation rates, depending on the measurement method, were less than 32 cfm per person, so the analysis estimated the benefits of increases in ventilation rates in approximately 30% to 40% of buildings.

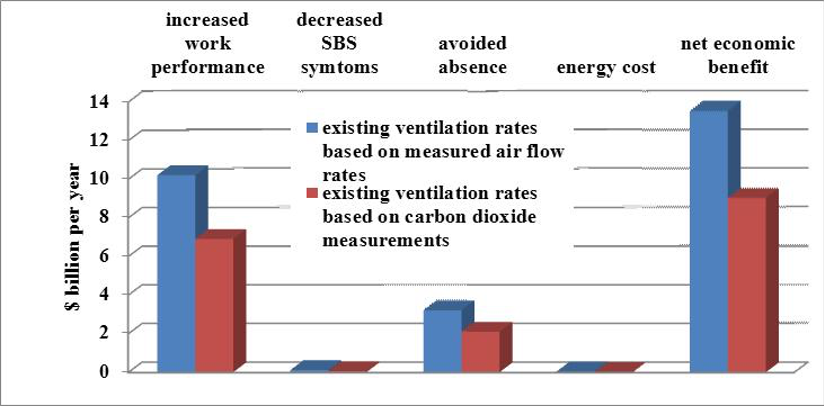

Various equations derived from published papers, many presented in other sections of this web site, were used to estimate the changes in work performance, sick building syndrome symptoms, and absence when ventilation rates were increased. The economic value of changes in sick building syndrome symptoms were based on an estimate of the annual health care costs of symptoms [4]. The economic value of changes in work performance and absence were calculated [2] based on the average total compensation of U.S. office workers [5]. The energy costs of increased ventilation rates were based on energy simulations of the U.S. commercial building stock [6, 7] and on energy prices for the commercial sector. The magnitude of the estimated benefits varied depending on the data used for existing office ventilation rates. Using one set of data, with ventilation rates based on measured air flow rates, the estimated benefits were a 1.1% average increase in performance in 12.4 million workers, an 18.8% average decrease in sick building syndrome symptoms in 12.4 million workers, and 10 million days of avoided absence. The estimated total annual economic value was $13.5 billion, with an annual energy cost of $0.04 billion. Most of the economic benefits were a consequence of increased work performance and decreased absence (see Figure 1).

Using another set of data that estimated existing ventilation rates in U.S. offices from peak indoor and outdoor carbon dioxide concentration data, the estimated annual economic value of the benefits was $9.0 billion, with annual energy costs of $0.02 billion. The published paper [2] also provides estimates of the costs and benefits of increasing ventilation to 21 cfm per person when the existing ventilation rate is less than this amount.

Figure 1. Two estimates of the annual benefits and costs of increasing ventilation rates in U.S. offices to 32 cfm per person when existing ventilation rates are less than 32 cfm per person.

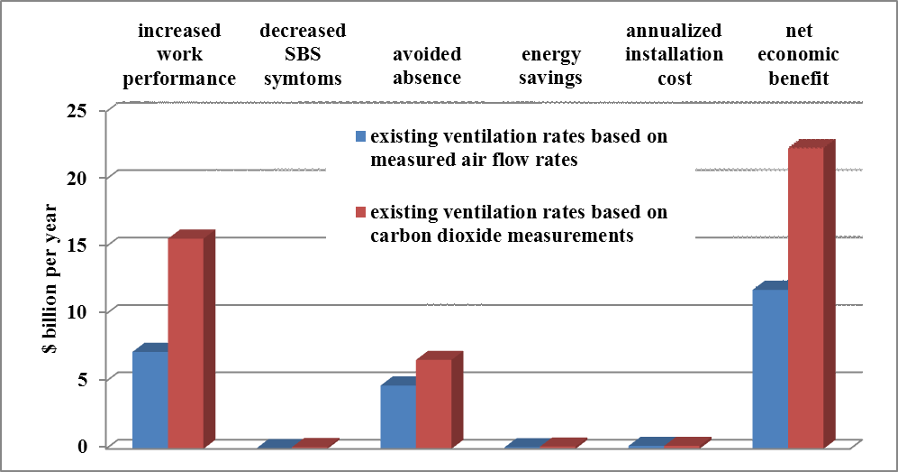

Another analysis [2] used the same basic methods to estimate the benefits of adding economizer systems to the 50% of the U.S. office building stock without economizer systems. An economizer is a control system that increases the ventilation rate above a minimum value when the additional ventilation will reduce the energy needed for air conditioning [8]. Economizers increase annual-average ventilation rates while saving energy. The increase in ventilation rates with the addition of economizers and the energy savings from economizers were derived from energy simulations of office buildings with and without economizers. The estimated benefits of adding economizers were similar in magnitude to the benefits of increasing ventilation rates to 32 cfm per person, with total annual economic benefits of $12 to $22 billion. Most of the projected economic benefits were a consequence of increased work performance and decreased absence. Adding economizers was projected to reduce energy costs by approximately $0.15 billion. The estimated annualized installation cost for economizers, spread over the expected system lifetime, was $0.22 billion

Figure 2. Two estimates of the benefits and costs of adding economizers in U.S. office buildings without economizers.

Very similar analysis methods were employed to evaluate the impacts of increasing ventilation rates or adding economizers in U.S. office buildings, using a hypothetical base case in which all offices currently have a minimum ventilation rate (when economizers are not activated) of 17 cfm per person [9]. The 17 cfm per person base rate is the required minimum ventilation rate for office space with the default occupancy density as prescribed in the key U.S. ventilation standard [1]. The estimated annual economic benefits were $13 billion for increasing minimum ventilation rates from 17 to 21 cfm per person, $38 billion for increasing minimum ventilation rates from 17 to 32 cfm per person, and $33 billion for increasing ventilation rates by adding outdoor air economizers for the 50% of the office floor area that currently lacks economizers. Benefits of increasing minimum ventilation rates due to improved work performance, reducing sick building syndrome symptoms, and reduced absence far exceeded energy costs, while adding economizers yielded health, performance, and absence benefits along with energy savings.

Minimum ventilation rates in most existing office buildings could be increased by adjusting dampers in air handling systems. In some buildings, the capacity of heating and cooling equipment may be insufficient to accommodate the increased heating and cooling loads during periods of severe cold or hot weather; however, benefits would be reduced only slightly if the increases in ventilation rates were scaled back during the infrequent times of most severe weather to make it unnecessary to change heating and cooling equipment. To increase ventilation rates by adding economizers, addition of new hardware and controls would be necessary. For many packaged heating, ventilating, and air conditioning (HVAC) systems, manufacturers offer economizers as an option that can be bolted on to the existing HVAC system. In site-built HVAC systems, retrofits would be more complex and costly, but economizers could easily be included when HVAC systems were replaced. Economizer failures are common and annual maintenance expenditures of approximately $0.2 billion might be needed to maintain proper economizer operation [9].

1. ASHRAE, ANSI/ASHRAE Standard 62.1-2010. Ventilation for acceptable indoor air quality. 2010, American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc.: Atlanta, GA Available from: http://arco-hvac.ir/wp-content/uploads/2016/04/ASHRAE-62_1-2010.pdf.

4. EPA, U.S., Cost of illness handbook. 2002, U. S. Environmental Protection Agency: Washington, DC.

5. Bureau of Labor Statistics. Employer cost for employee compensation - June 2008. 2008 [cited 2011; Available from: http://www.bls.gov/news.release/archives/ecec_09102008.pdf.